Easton ACC History

Easton originated carbon arrows all the way back in 1982, but it was the Easton X7 aluminum shafts that won the Olympic Games in 1972, when archery returned to the modern games. They also won the games in 1976, and 1980. But Easton’s first carbon A/C shafts were used to win the 1984 Olympic Games and have won every Olympic title since then, with the A/C/E taking the titles in 1988 and 1992, since then the X10s have always won.

In 1990, Easton introduced the affordable, high-performance A/C/C shaft series. The A/C/C part stands for Aluminum/Carbon/Competition – and was personally designed by Jim Easton. It started life with 12 original shaft sizes, and three more, weaker spine sizes were added a few years later after introduction – so now there is a total of 15 sizes, ensuring a correct tune for nearly every archer.

A/C/C still represents one of the most accurate, easily tuned, durable, safe and high performance carbon arrow shafts ever made. It, like all of Easton’s A/C shafts, is also made in the USA, at the Easton factory in Salt Lake City, Utah or was prior to 2021.

Design and Construction

The custom design of the A/C/C creates a low-drag, higher performing arrow with incredible spine and weight precision. The custom aluminum core allows point and nock components to be installed inside the shaft, flush with the shaft wall for the best aerodynamic characteristics.

The high-strength 7075 aluminum core provides strength needed to prevent crushing or splitting of the carbon fiber, and unlike ordinary carbon arrows, the construction of the A/C/C allows 100% of the carbon fibers to run parallel along the full length of the shaft, for maximum efficiency- maximum stiffness with minimum weight.

Easy Tuning

A/C/C shafts have always been custom spine tuned for extreme spine precision, with a 100% spine check 360 degrees around the shaft, and precision electronic weight matching for every shaft. This means A/C/C shafts have uniform, precise spine and weight tolerances within any given size.

Every size of A/C/C has a predictable tuning characteristic, because the spine to weight ratios of each size were carefully engineered.

There are eight different custom A/C/C internal diameters depending on the spine size of the shaft, so you need to know the core tube size to decide on point selection.

Nomenclature (Symbols on the shaft!)

There are three separate descriptors printed on each shaft.

- Number of carbon wraps

- Core tube diameter

- Static spine value (ATA/ASTM standard)

So, for example, you might see this on your A/C/C’s:

3-18/560

3 is the number of carbon wraps, 18 is a 0.218 diameter core tube, and 560 is the standard spine value.

Simple enough.

But what about sizes like:

3L-18/620 ?

In this example, the “3L” designation means there is less than 3 full layers of the specific carbon fiber used on the shaft (about 2.7 layers), because it has been “spine tuned” to the 620 spine value shown on the rest of the label. It still uses the -18 core compatible components, but the “3L” designation points to a weaker spine value with the same baseline shaft size.

In fact, one series of shafts built on the 0.204 core has three different spines as follows:

3-04/680

3L-04/750

3X-04/830

In this case, the “X” designation reflects an even thinner carbon jacket, about 2.3 layers of carbon.

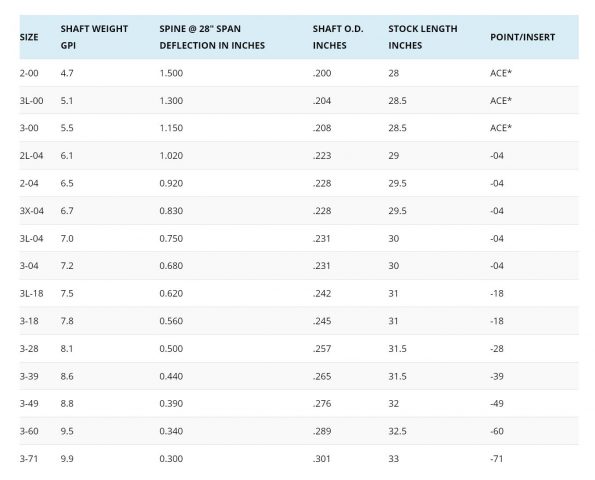

Easton ACC Spines

300, 340, 390, 440, 500, 560, 620, 680, 750, 830, 920, 1020, 1150, 1300, 1500

Easton ACC Int. Diameters / Point Insert Sizes

00, 04, 18, 28, 39, 49, 60, 71

Easton Arrow Spine Chart

Click on the image to enlarge it.

Easton ACC Components

In the Easton 2020 catalogue the ACC was available with a NIBB point, one-piece parabolic point or an RPS insert point. There was also an RPS insert and half-out insert. Easton provided two nocks the G Nock small 4mm at 7 grains and the Deep Six 4mm nock weighing 6 grains.

Easton ACC Advantages

The Easton ACC arrow is such a great quality arrow and reasonably priced and should last a long time.

Some archery retailers allow you to purchase the shafts in singles, which is great if you lose one or break one or if you just want to add to a set you have.

This is the arrow with lots of spines, so there should be an arrow for most archers.

Easton ACC arrows are easy to find 2nd hand on selling sites – Easton ACC on eBay

The ACC is an all-rounder, it’s a great arrow for outdoors and indoors

ACC arrows with their carbon wraps make it easier to pull out of targets on a wet day, certainly easier than an aluminium arrow which is smooth and squeaks as you pull it out of foam on a wet day.

ACC arrows are easy to maintain they have a good point fit and are easy to work with when glueing on fletchings and vanes.

Easton ACC Disadvantages

There are only a couple of disadvantages to the ACC, and the first one is their diameter and speed. If you require a lower spine like a 500 then the arrows get decidedly fatter and so slower. You will be fine on a high numbered spine as the arrows will then be quite thin.

The other problem is the confusion you may have with all the different point sizes and which point to buy to match the arrows as there are a lot of different arrow diameters in the Easton ACC range.

RIP Easton ACC Arrows!

Well since I made the video about Easton ACC arrows in 2020, Easton decided to stop making them as they did not appear in their Easton Catalogue 2021. So the major problem now is you may find it hard to buy them new or even second hand over time.

My Easton ACC Video

I made a video all about the Easton ACC video so if you want to head on over to YouTube and watch it, please do. But don’t forget to like it and subscribe to my channel!