Easton ACE History and Barrelled shafts

In the late 80’s Jim Easton devised a method to improve on the parallel design, and create a barreled Aluminum-Carbon shaft- this became the A/C/E, introduced in 1987 and used by Jay Barrs to win the 1988 Olympic Games, as well as to set multiple world records of the time (some of which lasted more than 20 years).

By making the rear half of the shaft less stiff and much lighter in mass than the front or the center, clearance for finger shooters is improved from recurve bows. This characteristic also makes small variations in finger release much less of a problem. By shifting the shaft balance point forward, front of center balance is improved, which allows for improved wind performance from the arrow shaft.

It is much more difficult to build a barreled shaft with excellent tolerances than either a parallel or a single-tapered shaft. A tremendous investment in technology and considerable experience is needed to successfully build such arrow shafts consistently.

Easton ACE Weight Codes – ‘C’ Numbers

Most top end Easton arrows carry a weight coding. This appears as a “C” number on the shaft such as C1, C2, C3 etc. After the shafts have been made they are carefully weighed and sorted into batches to ensure that you get a dozen shafts that are as close in weight as possible.

When a production run (of many thousands of arrows) is created, each arrow shaft is individually weighed after final spine-tuning, and the entire population of arrow shafts can be charted (as with a bell curve) for weight. Typically, there is about a 5 to 6 grain total spread from lightest to heaviest among the thousands of arrows in a given run of a given size, and this is subdivided into less than one grain increments for assignment to a specific code- and even finer graduations for each individual dozen.

Here are the key points to understand the significance of this.

- All ACE and X10 weight codes cover a total spread of 1.5 grains (.097 gram)

- All packaged ACE and X10 shafts are held to a weight tolerance of +/- 0.5 grains in that specific package

- It is easily possible for an archer to mix shafts from two adjacent weight codes with no ill effect (”heavy” C.2 and “light” C.3 for example) because by the time you cut the shafts, apply fletching, points, and perhaps an arrow wrap, the fine distinction in weight between one group and other is “blurred” a bit. In reality a three grain spread is undetectable by even the highest level archer.

You may find it harder to find certain C numbers now as the manufacturing process get better and better and less outliers are produced in large numbers. But you can always order them if required.

Easton ACE Pro’s

A great quality carbon aluminium arrow with its barrelled design it is a very light arrow, good for sight marks and speed. The Easton ACE is also a good all-rounder, it is great for target archery outdoors and indoors also used a lot for field archery.

Having a carbon wrapped arrow makes it easier to pull out of targets on a wet day, especially compare to an aluminium arrow.

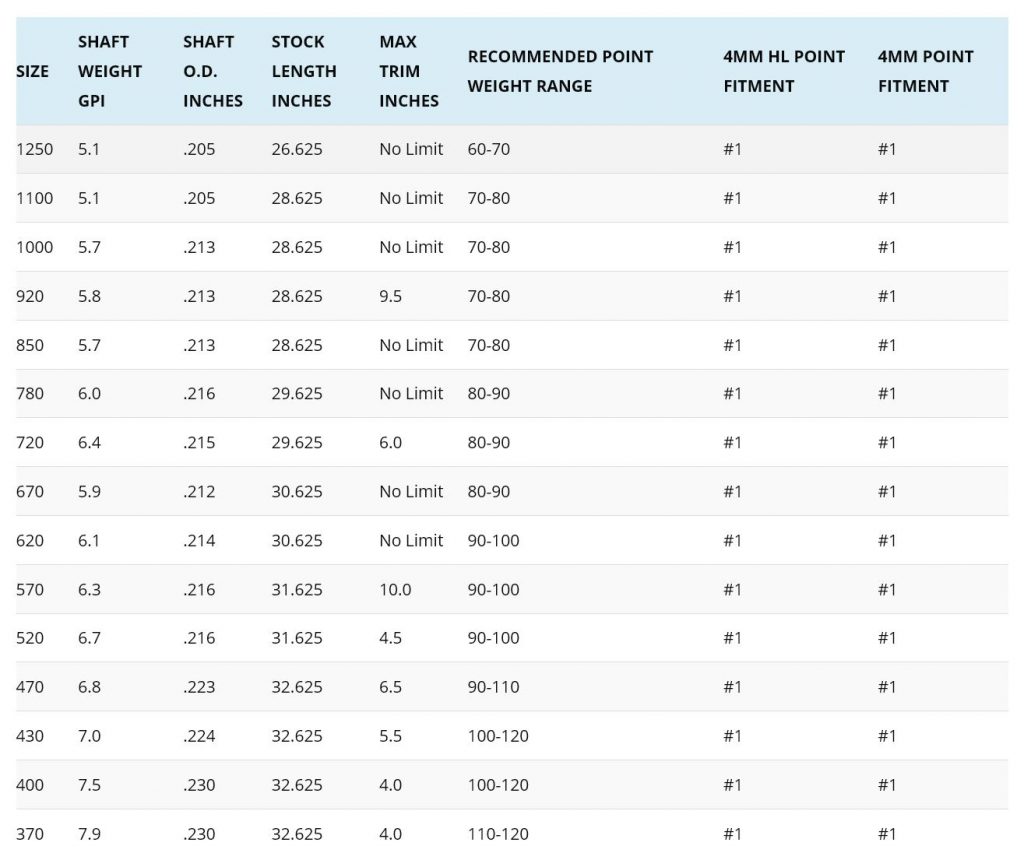

The Easton ACE also comes in lots of spines sizes, 15 in total.

The arrows also take a number of different manufacturers nocks, so you are not tied to Easton nocks you can try Beiter and Bohning nocks for example.

Easton ACEs are also easy to maintain. They have a good point fit and are easy to work with when attaching fletchings, wraps or spin wings.

Easton ACE Cons

There are not many cons to the Easton ACE arrows, other than cost and that you cannot usually purchase them singularly, you have to purchase them in batches of 12.

Easton ACE Arrow Spines

1250, 1100, 1000, 920, 850, 780, 720, 670, 620, 570, 520, 470, 430, 400, 370

Easton ACE Arrow Spine Chart

Click on the image below to enlarge it.

Easton ACE Specifications

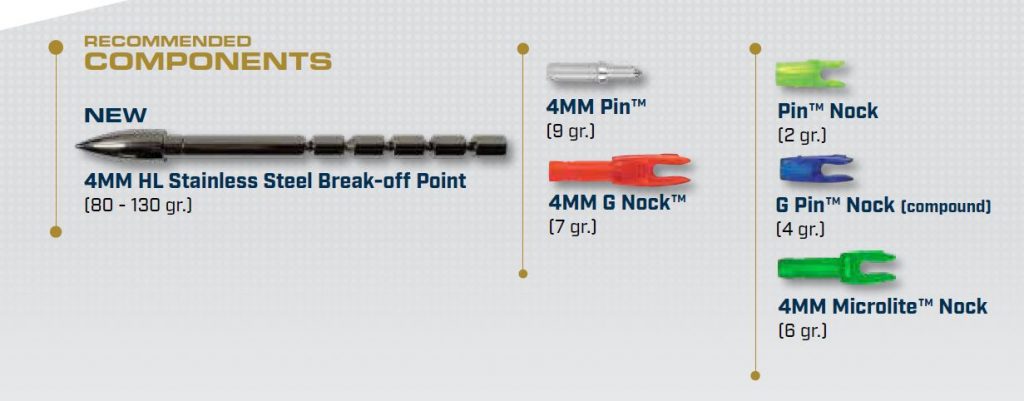

Easton ACE Components

Pre 2021 ACE components

Prior to 2021 you could get a variety of points from Easton including the A/C/E Stainless steel break off point in the 3 sizes, a one-piece pont and an insert and screw-in point. In 2021 all these points were replaced by a very long single break-off point, which allows you to select your own weight from 80 grains to 130 grains.

ACE pins are available for the nock end, which I also use together with Beiter pin nocks. But Easton produce their own pin nocks, g pin nocks, g nocks and a microlite nock for the ACE.

2021 onwards ACE components

My Easton ACE YouTube Video

You can watch all about the Easton ACE in a video I made on my YouTube channel. Just don’t forget to like the video and subscribe to my channel.